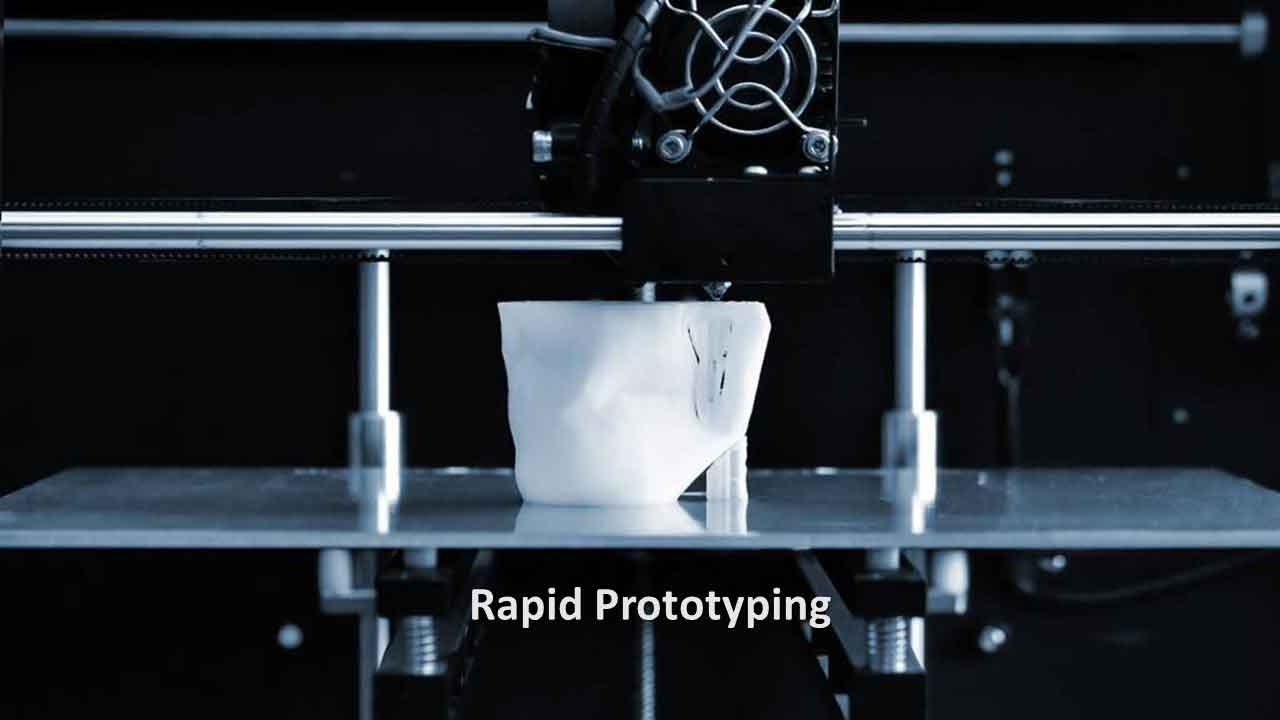

Role of Rapid Prototyping

Rapid prototyping is a process of quickly creating a prototype of a product, typically to test its functionality or design. This process is often used in product development to test and validate ideas, as well as refine designs before entering into full-scale production.

Rapid prototyping allows businesses to quickly iterate on their products and test them with consumers to identify the best possible design and features. It can also be used to create functional models for marketing purposes or to demonstrate how a product might look and feel when completed.

Rapid Prototyping Process

The rapid prototyping process consists of several steps. The first step is concept generation, where ideas for the new product or system are generated and evaluated. Once potential concepts have been identified, the next step involves creating a prototype model of the product or system using 3D printing technology, computer-aided design (CAD) software, or other rapid fabrication techniques.

After this model has been created, it can then be tested for functionality through simulations and physical experiments. Finally, any necessary changes can be made before production begins on an industrial scale.

Rapid prototyping enables designers to test their ideas much faster than traditional methods would allow them to do so – instead of having to wait months for parts to be produced in a factory setting before they can start testing their designs, they can now develop working samples within days or even hours using 3D printers and other fabrication techniques available today.

Rapid prototyping is a process that has become increasingly popular in the manufacturing industry in recent years. It involves the use of computer-aided design (CAD) and 3D printing technologies to quickly create physical prototypes of products or components without the need for traditional manufacturing methods.

Rapid Prototyping Applications

Rapid prototyping can be used for a variety of applications, from product development and testing to producing small-scale production runs.

In product development, rapid prototyping is an invaluable tool that allows engineers and designers to quickly create physical models of their designs for evaluation purposes. This helps them identify any potential problems with the design before beginning full-scale production, saving time and money in the long run.

By creating multiple iterations of a prototype, designers can optimize their product’s form factor, function, or aesthetics before investing significant resources into mass production.

Rapid prototyping also makes it possible to produce short-run manufacturing jobs at low cost without having to invest in expensive tooling or specialized equipment. This allows companies to test out new products or components without investing large sums into production machinery until they are sure about its success rate on the market.

Additionally, by utilizing 3D printing technology companies can rapidly produce custom parts with intricate geometries which may not be achievable using conventional machining processes

Conclusion

Rapid prototyping is an invaluable tool that enables businesses to quickly and cost-effectively create prototypes of their products. It helps reduce the time to market for new products and allows for quick design iteration.

Rapid prototyping also helps reduce costs by eliminating costly physical prototypes requiring more time and material resources. By allowing companies to prototype their ideas rapidly, it has become a powerful tool in product development, enabling businesses to bring innovative products to market faster than ever before.